48+ Centrifugal Pump Viscosity Range

48+ Centrifugal Pump Viscosity Range. Dalam pekerjaan di bengkel-bengkel otomotif, baik itu bengkel motor maupun bengkel mobil membutuhkan centrifugal pump untuk membongkar pasang komponen. Karena tidak mungkin seorang mekanik menggunakan tangan kosong dalam melakukan perbaikan motor/mobil. centrifugal pump ini ada karena hampir semua komponen di dalam kendaraan bermotor baik itu motor, mobil, bus dll disatukan menggunakan baut yang bisa dilepas dengan centrifugal pump alat-alat bengkel.centrifugal pump dengan artikel 48+ Centrifugal Pump Viscosity Range berikut ini

5 5 Things Power Plant Engineers Need to Know About iPumpsi Sumber www.power-eng.com

The Importance of iViscosityi in Different Applications Sumber www.pumpsandsystems.com

Chemical Process Technology June 2008 Sumber webwormcpt.blogspot.sg

Chemical Process Technology June 2008 Sumber webwormcpt.blogspot.my

SHC iRangei Horizontal icentrifugali mechanical seal ipumpsi Sumber www.crestpumps.co.uk

iPumpsi CM4120 D Caspary February ppt video online download Sumber slideplayer.com

Reciprocating ipumpsi Sumber www.slideshare.net

Effect of iViscosityi on iPumpi Performance Campbell Tip of Sumber www.jmcampbell.com

Equations correct icentrifugali ipumpi curves for iviscosityi Sumber www.ogj.com

iPumpi Info Reciprocating iPumpsi vs Multi Stage iCentrifugali Sumber amb-pumpinfo.blogspot.gr

EDUR Stainless Bloc Standard iCentrifugali iPumpi Hydro Sumber www.hydroinnovations.com.au

iCentrifugali CIRCOR Sumber www.circorpt.com

Alfa Laval Close Coupled Sanitary iPumpsi Valutech Inc Sumber www.valutechinc.com

iCentrifugali ipumpsi designed for sanitary applications FRASERS Sumber www.frasers.com

An Experimental Study on the Effect of Oil iViscosityi and Sumber fluidsengineering.asmedigitalcollection.asme.org

Considering the effect of crude oil iviscosityi on pumping Sumber www.jmcampbell.com

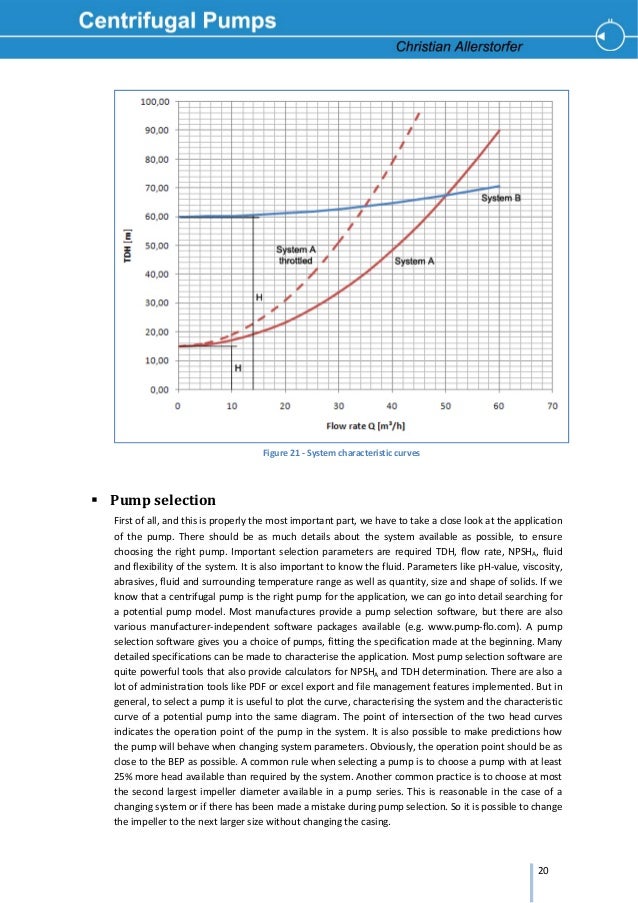

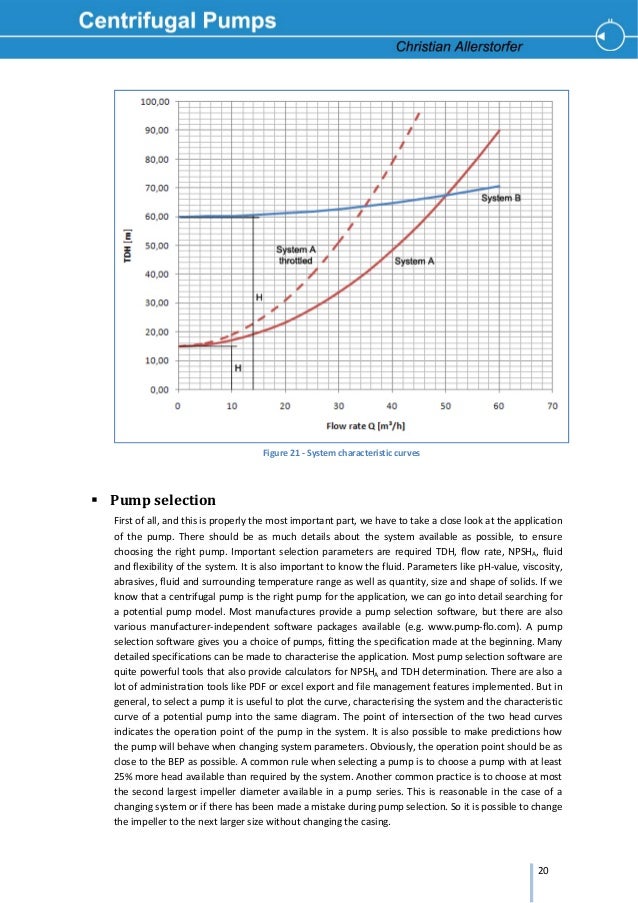

Bachelor thesis icentrifugali ipumpsi christian allerstorfer Sumber www.slideshare.net

Industrial iPumpsi iCentrifugali iPumpsi Authorized Wholesale Sumber www.indiamart.com

TOPLINE TF C216MD iCENTRIFUGALi iPUMPi BreweryTrader Sumber brewerytrader.com

Sanitary Stainless steel High iViscosityi Rotary Lobe iPumpi Sumber www.cnsunthai.com

Cast Iron iCentrifugali iPumpi CHC M iPumpi iRangei Crest iPumpsi Sumber www.crestpumps.co.uk

Cast Iron iCentrifugali iPumpi Chemical iCentrifugali iPumpsi Sumber www.crestpumps.co.uk

Cause of ipumpi overloading EnggCyclopedia Sumber www.enggcyclopedia.com

Industrial iPumpsi Sumber motorsandpumps.net

iCentrifugali ipumpi ESTAMPINOX EFI iCentrifugali ipumpsi INOXPA USA Sumber www.inoxpausa.com

TOP FLOA TF C328 iCentrifugali iPumpsi 3 A a Top Line Sumber www.toplineonline.com

IH 65 50 Single Stage End Suction Chemical iCentrifugali iPumpi Sumber gtopumps.com

New irangei of magnet driven ipumpsi compliant with API 685 Sumber www.bedu.eu

TOP FLOA TF C216 iCentrifugali iPumpsi 3 A a Top Line Sumber www.toplineonline.com

M iPumpsi magnet drive icentrifugali vane and turbine ipumpsi Sumber www.michael-smith-engineers.co.uk

iCentrifugali iPumpsi HpE Process Ltd Sumber www.hpeprocess.com

iPumpi Type Archives Page 3 of 3 Netco iPumpsi and Equipment Sumber www.netcopumps.com.au

Stainless Steel Split Casing Fan iPumpi Buy Fan iPumpi Sumber www.alibaba.com

iCENTRIFUGALi iPUMPSi Sumber johnbrooks.co.nz

Wallace iPumpsi Commercial Rural and Irrigation Sumber www.wallacepumps.co.nz

5 5 Things Power Plant Engineers Need to Know About iPumpsi Sumber www.power-eng.com

Viscosity KSB

The HI technique see Fig 3 Viscosity was measured only at n s 15 to 20 rpm and in this narrow application range leads to similar results to the KSB technique see Fig 4 Viscosity which was measured in the n s range from 6 5 to 45 rpm and at viscosities of up to I1 2 z 4000 A 10 a 6 m 2 s The use of the two diagrams is explained by

The Importance of iViscosityi in Different Applications Sumber www.pumpsandsystems.com

viscosity range for centrifugal pumps Pump engineering

viscosity range for centrifugal pumps mirghaffari Mechanical OP 2 Jan 13 12 59 hi everybody in our crude oil project i am face with a oil with high viscosity viscosity 120 CP our Preference is usage of centrifugal pumps could you please help me that is possible or not do yo have any experiance to pump this viscose liquid with

Chemical Process Technology June 2008 Sumber webwormcpt.blogspot.sg

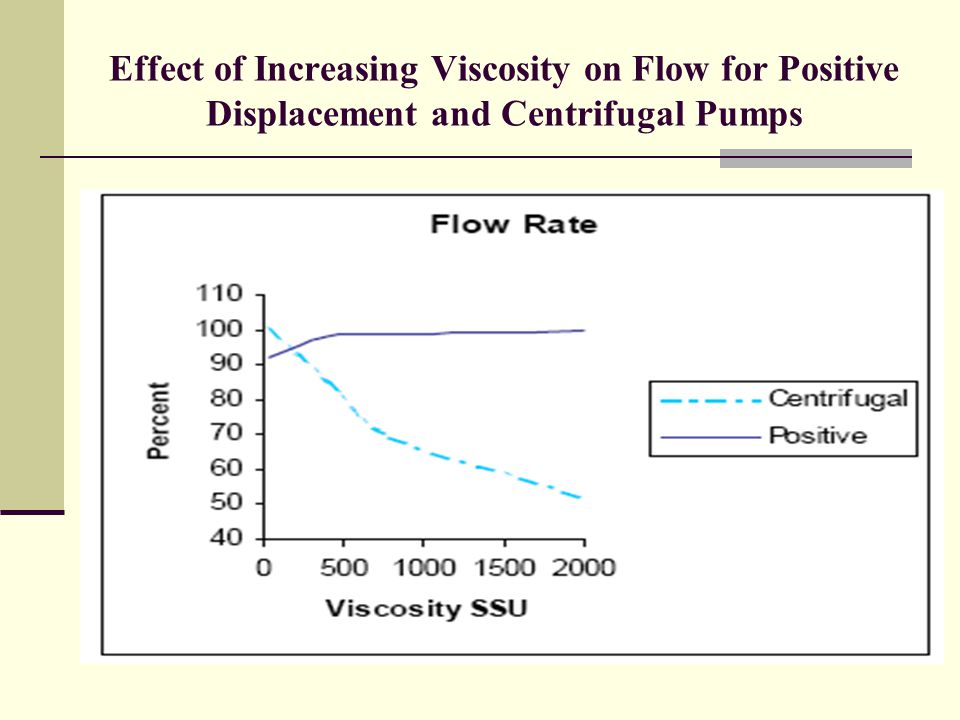

Selecting a Centrifugal Pump to Handle a Viscous Liquid

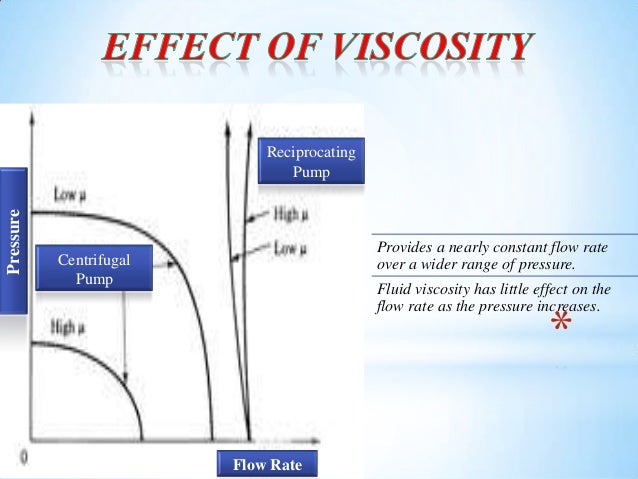

Use of centrifugal pumps for a viscosity over 300 cen viscosity may range upward to 3 300 centistokes It must be noted that extremely viscous fluid handling applications are best left to positive displacement rather than centrifugal pumps Selecting a Centrifugal Pump a

Chemical Process Technology June 2008 Sumber webwormcpt.blogspot.my

Fluid viscosity and density A pump useras guide Grundfos

aViscosity is essentially resistance to flow and this has implications for pumps a says SAren Mortensen aIf you have a high viscosity sticky fluid on your hands it clings and itas much harder to remove than a low viscosity fluid It is the same in a pump where you have impellers to move the fluid

SHC iRangei Horizontal icentrifugali mechanical seal ipumpsi Sumber www.crestpumps.co.uk

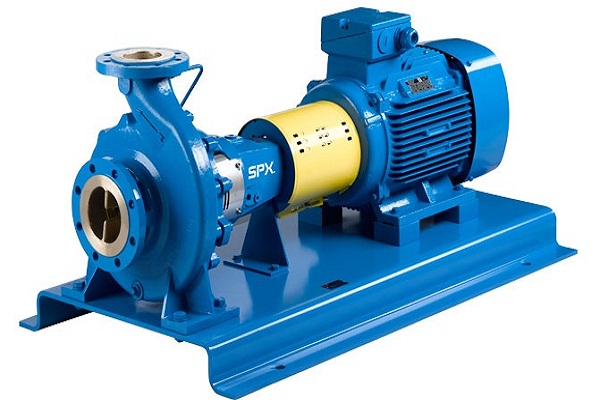

Centrifugal Pumps Manufactured Pumps DAE Pumps

Centrifugal pumps are among the most common type of pumps found in industrial applications Centrifugal pumps contain one or more impellers that move fluid by rotation This design allows the pumps to be used for a wide range of industries Centrifugal pumps are preferred for low viscosity liquids and high flow rates

iPumpsi CM4120 D Caspary February ppt video online download Sumber slideplayer.com

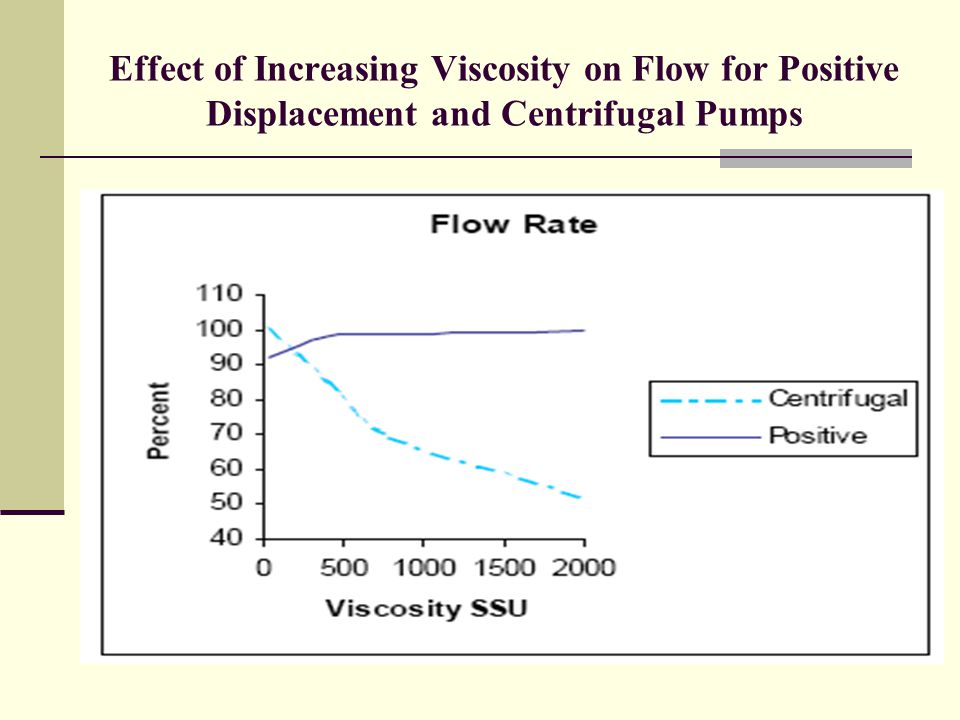

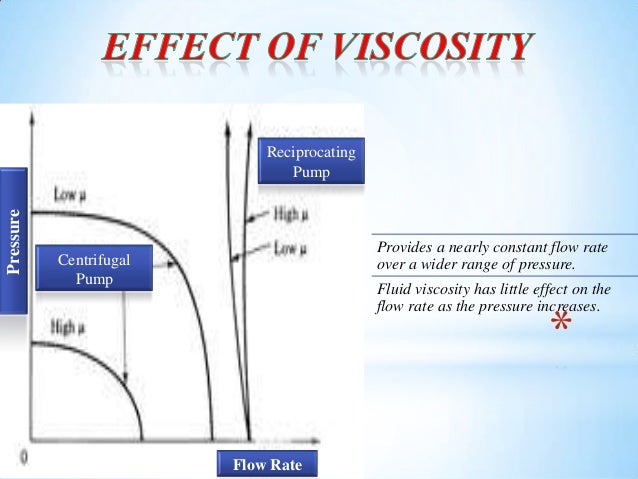

The Effects of Viscosity On Systems And Pump Selection

04 09 2014AA Viscosity is a fluid property which is resistance to shear when energy is applied This characteristic must be taken into account when making process pump selections and in determining friction losses in a fluid process system Centrifugal pump performance is based on testing with water

Reciprocating ipumpsi Sumber www.slideshare.net

The Influence of Viscosity on Pump Digital Scholarship

The influence of viscosity on the performance of centrifugal pumps has not received up to the present the systematic attenA tion of the pump engineers which this problem deserves in view of the ever increasing use of the centrifugal pump for the transA port of viscous liquids A a

Effect of iViscosityi on iPumpi Performance Campbell Tip of Sumber www.jmcampbell.com

Equations correct centrifugal pump curves for viscosity

Equations correct centrifugal pump curves for viscosity Also the pump must have a conventional design and the kinematic viscosity of the liquid pumped should range between 4 and 3 000 cst

Equations correct icentrifugali ipumpi curves for iviscosityi Sumber www.ogj.com

iPumpi Info Reciprocating iPumpsi vs Multi Stage iCentrifugali Sumber amb-pumpinfo.blogspot.gr

EDUR Stainless Bloc Standard iCentrifugali iPumpi Hydro Sumber www.hydroinnovations.com.au

iCentrifugali CIRCOR Sumber www.circorpt.com

Alfa Laval Close Coupled Sanitary iPumpsi Valutech Inc Sumber www.valutechinc.com

iCentrifugali ipumpsi designed for sanitary applications FRASERS Sumber www.frasers.com

An Experimental Study on the Effect of Oil iViscosityi and Sumber fluidsengineering.asmedigitalcollection.asme.org

Considering the effect of crude oil iviscosityi on pumping Sumber www.jmcampbell.com

Bachelor thesis icentrifugali ipumpsi christian allerstorfer Sumber www.slideshare.net

Industrial iPumpsi iCentrifugali iPumpsi Authorized Wholesale Sumber www.indiamart.com

TOPLINE TF C216MD iCENTRIFUGALi iPUMPi BreweryTrader Sumber brewerytrader.com

Sanitary Stainless steel High iViscosityi Rotary Lobe iPumpi Sumber www.cnsunthai.com

Cast Iron iCentrifugali iPumpi CHC M iPumpi iRangei Crest iPumpsi Sumber www.crestpumps.co.uk

Cast Iron iCentrifugali iPumpi Chemical iCentrifugali iPumpsi Sumber www.crestpumps.co.uk

Cause of ipumpi overloading EnggCyclopedia Sumber www.enggcyclopedia.com

Industrial iPumpsi Sumber motorsandpumps.net

iCentrifugali ipumpi ESTAMPINOX EFI iCentrifugali ipumpsi INOXPA USA Sumber www.inoxpausa.com

TOP FLOA TF C328 iCentrifugali iPumpsi 3 A a Top Line Sumber www.toplineonline.com

IH 65 50 Single Stage End Suction Chemical iCentrifugali iPumpi Sumber gtopumps.com

New irangei of magnet driven ipumpsi compliant with API 685 Sumber www.bedu.eu

TOP FLOA TF C216 iCentrifugali iPumpsi 3 A a Top Line Sumber www.toplineonline.com

M iPumpsi magnet drive icentrifugali vane and turbine ipumpsi Sumber www.michael-smith-engineers.co.uk

iCentrifugali iPumpsi HpE Process Ltd Sumber www.hpeprocess.com

iPumpi Type Archives Page 3 of 3 Netco iPumpsi and Equipment Sumber www.netcopumps.com.au

Stainless Steel Split Casing Fan iPumpi Buy Fan iPumpi Sumber www.alibaba.com

iCENTRIFUGALi iPUMPSi Sumber johnbrooks.co.nz

Wallace iPumpsi Commercial Rural and Irrigation Sumber www.wallacepumps.co.nz

loading...

0 Comments